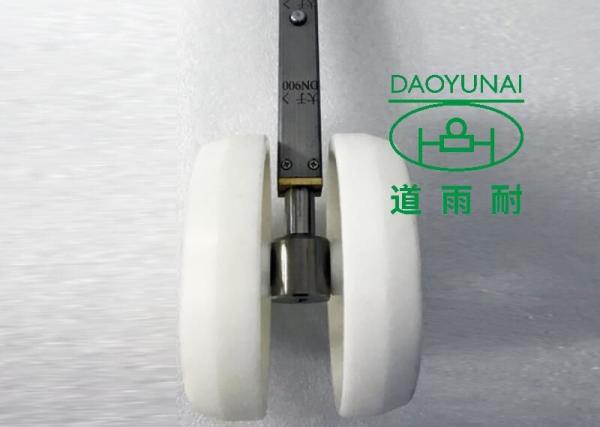

Advanced customized headlamp wheel rack of UV curing equipment

manufacturer

Operation process of UV CIPP curing repair technology

Ultraviolet UV CIPP light-curing repair technology is used for the

overall trenchless repair of underground municipal drainage pipes.

The pipe diameter covers typical sizes. It is a process of in-situ

curing method. The repair length can pass through several sections

of a manhole at a time, ranging from 50m to 200m. The repair time

is 3-6 hours. It is mainly aimed at sewage pipes and rainwater

pipes and is applicable to various common pipes, such as plastic

pipes, concrete reinforced pipes, cast iron pipes, brick pipes,

etc. It is widely used all over the world because of its wide range

of applications, fast construction speed, and superior performance

of repair materials.

The in-situ curing method, which originated in Britain in the

1970s, is called cured in place pipe in English, or CIPP for short.

It forms a complete and new pipeline with structural strength

inside the existing pipeline.

The basic process is to cut the corresponding length of the

pre-impregnated resin hose (glass fiber or non-woven fabric)

according to the length of the pipeline to be repaired, then put

the hose into the pipeline to be repaired through specific

processes, such as turning and dragging, and then solidify the hose

through corresponding equipment, such as hot water boiler heating,

steam heating or ultraviolet light irradiation, so as to achieve

the purpose of repair.

UV CIPP, as a process of in-situ curing, refers to putting the glass fiber

hose impregnated with resin into the pipeline by dragging, and then

irradiating it with UV equipment to quickly cure and complete the

repair.

| How | Fixed length for different pipes |

| Application | Sewers |

| QTY | Any |